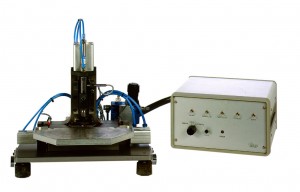

PS2S A fully automatic hammering press for punching out blanks from a flat ribbon of metal. This 30 Ton high precision press is extremely versatile and high precise, leaving no room for error with its micrometric accuracy level. An automatic feeding system feeds the ribbon into the unit at precise and pre-set pitches. The toggle system based hammering mechanism ensures total and controlled power at every stroke with a minimum force on the internal mechanisms thus reducing wear and maintaining high accuracy throughout the machines life. Tool change is fast and easy thanks to the rapid blocking system. A very silent machine, it is provided with a pneumatic clutch and brake system, and its own forced lubrication system. PSMA A fully automatic system for forming the lobster clasp shell from the cutout which has been almost completely punched out from a strip. The strip is loaded onto the machine in the form of a reel which is then fed through a final cutting section where the piece is finally cut out completely. At this point it goes to the folding and soldering mechanisms, where the clasp shell is processed and discharged, ready for final assembly. MIM A semi-automatic unit which simply and effectively produces a spring from stainless steel wire and then inserts it into a waiting trigger. The stainless steel wire is loaded on the machine via a reel. The triggers are placed in a turning tray which rotates the trigger to the spring insertion station, here the spring is formed and then inserted, once completed the trigger/spring assembly is discharged. Rapid tool changeover allows different size triggers to be processed on the same machine. MAM A semi-automatic unit which simply but effectively assembles lobster claw type clasps by inserting the trigger complete with spring into the shell. Rapid tool changeover allows different size clasps to be processed on the same machine. Shell and trigger/spring assemblies are positioned on the machine by the operator, and with the clasp is assembled by a touch of a button. MAMA1 Fully automatic system for the assembly of lobster clasps. The unit assembles together the 3 key parts of a lobster clasp; shell, trigger and spring. Notes This unit is able to process all kinds of metal Download Technical File

Soldering can be had either with gas/flame system or via high speed laser.

Soldered shells are loaded into a vibrating hopper, stainless steel wire is fed from a reel in order to make the spring, and the trigger is punched out from a strip of semi-finished triggers. Thanks to its synchronised transport system & work stations the unit has a capacity of 50 finished triggers per minute.

Once passed the testing station, the finished clasp is discharged from the machine.PS2S Technical features Press power 30 Ton Production speed up to 300 strokes/min Feed pitch up to 40 mm Ribbon width up to 50 mm Useful stroke 116 to 126 mm Technical data Voltage (threephase) 400 V 50 Hz Power 3 kW Compressed air 60 lt./min (dry) at 6 bar Dimensions 100 x 90 x 200(h) cm – 1,250 kg packing 122 x 122 x 226(h) cm – 1,400 kg PSMA Technical features Production speed 45 – 50 pieces/min Technical data Voltage 230 V 50 Hz Power 0.30 kW Compressed air 50 lt./min (dry) at 6 bar Soldering gas 3.50 lt/min Dimensions 85 x 70 x 167 (h) cm -186 kg Packing 90 x 90 x 168 (h) cm – 310 kg MIM Technical features Max. production speed 20 – 30 triggers/min Technical data Voltage (single phase) 230 V 50/60 Hz Power 0.5 kW Compressed air 90 l/min (filtered) at 6 bar Dimensions 47 x 76 x 150(h) cm – 82 kg packing 64 x 147 x 75 (h) cm – 140 kg MAM Technical features Max. production speed 6 – 12 pieces/min Technical data Voltage (single phase) 230 V 50/60 Hz Power 0.1 kW Compressed air 3.5 lt./min (dry) at 6 bar Dimensions 75 x 40 x 40(h) cm – 28 kg packing 57 x 78 x 56 (h) cm – 48 kg MAMA1 Technical features Max. production speed 50 clasps/min Clasp sizes 8 – 16 Technical data Voltage (single phase) 230 V 50/60 Hz Power 2,6 kW Compressed air 114 l/min (filtered) at 6/7 bar Dimensions 69 x 82 x 210(h) cm- 265 kg Packing 89 x 93 x 176 (h) cm – 355 kg