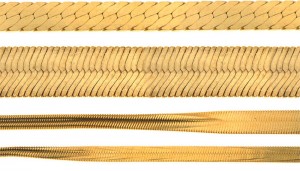

The PB2 automatic hammering press is more than just a hammering unit. Thanks to the unique design, and conception, the machine actually moulds the piece it is processing to a new form and internal structure. This gives the hammered material a perfectly uniform structure. The hammering process has an accuracy of 0.01 mm thus greatly improving production efficiency, in that less material will have to be removed in surfacing procedures. The perfect finish of the hammered surface and the absence of lateral trimmings allow to reduce process time to an absolute minimum.Technical features Press power 150 Tons Feed pitch up to 10 mm Process width 25 mm Production speed up to 400 strokes per minute Technical data Voltage supply (three phase) 400 V AC 50 Hz Power supply 16 kW Air supply 2 l for each work cycle at 6 bar Water supply 300 l/h at 5 bar and 16 – 24 °C Dimensions 190 x 145 x 180(h) cm – 2,200 kg packing press 137 x 139 x 207(h) cm – 2215 kg control panel 153 x 75 x 124(h) cm – 301 kg

Privacy Overview

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Read the complete privacy policy .