-

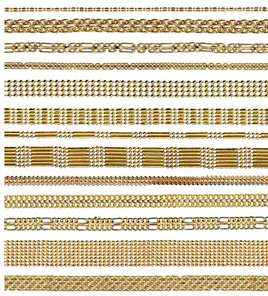

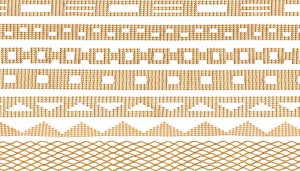

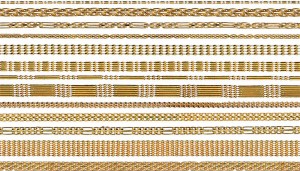

Automatic machine for the production of “Bismark” chains. The unit solders two or more chains together in parallel. The unit has a unique advancing system which automatically corrects any error between the chains pitches. The soldering process is carried out using a simple laser unit. Thanks to the speed and accuracy of the laser, the units are able to process over 800 links per minute, producing quality enhanced product. The laser can be external or optionally a built in diode laser. All of the machine is completely controlled by a microprocessor based control unit, which sees to controlling all facets of the process: chain feeding, laser shooting, etc. Laser soldering signifies high efficiency, low maintenance, reliability and ease of use Self centring tooling make tool changeover extremely fast and precise.

-

Technical features Max. production speed 800 links/min Max. process width 30 mm Wire Ø from 0.20 to 2.00 mm Technical data Voltage (single phase) 230 V 50/60 HZ Power 0.30 kW (1.3 kW with built in laser) Compressed air 35 l/min (filtered) at 6 bar Argon gas 5 l/min at 0.5 bar Dimensions 65 x 90 x 164(h) cm – 153 kg (192kg with laser) Packing 90 x 88 x 188 (h) cm – 250 kg (290kg with laser) Notes

The above data, features and characteristics are not binding. CIEMMEO s.r.l. retains the right to vary them at

any time without prior notice -