-

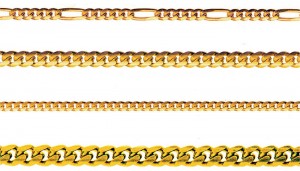

Automated and compact machine for faceting chains and chain ornaments. Fully programmable with 14 controlled axis allowing full flexibility of design cuts. Can be equipped with 2 fully independent easily changeable diamond mills, or spindles, (or a combination of both). Mills and spindles have rapid changeover connectors. It assures the highest speed productivity in its range of machines. The cutting wheels guarantee an elevated cutting speed giving maximum cutting efficiency and quality as well as maximum durability of the cutting diamonds. Optic fibres handle communication between the PLC and the synchronised brushless motors, which allow micrometric precision in positioning and speed. Chain positioning is fully mechanical, guaranteeing perfect positioning, as well as automatic pitch error recovery, along with the fastest speed possible All aspects of operator control are interfaced with a full touch screen control panel with program memorization capabilities as well as modem connection capabilities for remote assistance.

Industry 4.0 ready -

Technical features SFM Max. production speed 20 – 30 links/min* Cutting speed 1900 m/min/min Cutting wheels 2 Max. chain Ø 5.0 mm Technical data Voltage (single phase) 230 V 50/60 Hz Power 4.50 kW Compressed air 50 l/min (filtered) at 7 bar Dimensions 125 x 110 x 180 (h) cm – 405 kg Packing 135 x 120 x 200 (h) cm – 525 kg * speed depends solely on chain configuration

Note. The above data, features and characteristics are not binding. CIEMMEO s.r.l. retains the right to vary them at

any time without prior notice

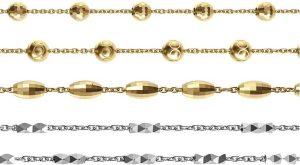

Automated and compact machine for faceting chains and chain ornaments. Fully programmable with 8 controlled axis allowing full flexibility of design cuts.

Automated and compact machine for drilling and/or calibrating threading holes of beads and balls . fully programmable with 4 controlled axis allowing full functionality and speed. It assures the highest speed productivity in its range of machines. Optic fibres handle communication between the PLC and the synchronised brushless motors, which allow micrometric precision in positioning and speed. Bead feeding and handling is fully mechanical, guaranteeing perfect positioning, along with the fastest speed possible. Beads are fed through a rotating hopper, channelled to a standby station, then positioned in the drilling position via suction. Once processed, the bead is blown into containment receptacle. All scrap is recovered either in the work area or aspirated with optional vacuum unit. All aspects of operator control are interfaced with a full touch screen control panel with program memorization capabilities as well as optional modem connection capabilities for remote assistance. Notes The above data, features and characteristics are not binding. CIEMMEO s.r.l. retains the right to vary them at any time without prior noticeTechnical features Max. production speed 20 – 30 beads/min* Drilling speed 6000 rpm Drilling stations 2 Bead Ø 2 – 10 mm Technical data Voltage (single phase) 230 V 50/60 Hz Power 1.80 kW Compressed air 1 lt./min (dry) 50 l/min (filtered) at 7 bar Dimensions 72 x 82 x 175 (h) cm – 246 kg packing 103 x 86 x 198 (h) cm – 370 kg

-

Automated and compact machine for faceting chains and chain ornaments. Fully programmable with 8 controlled axis allowing full flexibility of design cuts. Can be equipped with 2 fully independent easily changeable diamond wheels, or spindles, (or a combination of both). It assures the highest speed

productivity in its range of machines. The cutting wheels guarantee an elevated cutting speed giving maximum cutting efficiency and quality as well as maximum durability of the cutting diamonds.

Optic fibres handle communication between the PLC and the synchronised brushless motors, which allow micrometric precision in positioning and speed.

Chain positioning is fully mechanical, guaranteeing perfect positioning, as well as automatic pitch error recovery, along with the fastest speed possible All aspects of operator control are interfaced with a full touch screen control panel with program memorization capabilities as well as modem connection capabilities for remote assistance. -

Technical features SFM Cutting speed 1900 m/min/min Cutting wheels 2 Max. chain Ø 5.0 mm Technical data Voltage (single phase) 230 V 50/60 Hz Power 1.80 kW Compressed air 50 l/min (filtered) at 7 bar Dimensions 80 x 120 x 165 (h) cm – 275 kg Packing 85 x 85 x 193 (h) cm – 360 kg

The most innovative ice lathe available. This state of the art ice lathe revolutionizes the concept of ice lathes. The TG6 takes advantage of the most advanced electronic and computer technology to automate the work cycle. thanks to the new technologies used the precision is now measured by the micron(µm) . A complete new onboard refrigeration system allows automatic rapid icing and thawing. The new tool head has a total of 9 tools which are changed automatically according to the pre- set program. Notes This unit is able to process all kinds of metal

Up to three diamond tools work simultaneously, removing three times as much material per pass, and there is no downtime due to empty passes. Each type of work cycle can be programmed into the on board computer via a touch screen panel.

When needed a preprogrammed work cycle is called up and starts automatically. The unique internal design allows for a complete recovery of the gold dust. Any defect in the drums (or chain’s) surface can also be programmed into the machine so that the tool head follows the profile of the drum (or chain), thus prolonging the drums work life (and drastically reducing scrap).

Up to 9 different sets of chains (with different process programs) can be loaded onto the drum per single icing session, ideal for small sets of sample chains.Technical features Cylinder Ø – length Ø 505 – 290mm Rotation speed 500 rpm Minimum chain size 0.18 mm Freezing time 4 min Thawing time 1 – 2 min Technical data Voltage (threephase) 400 V 50/60 Hz Power 15 kW Compressed air 1 lt./min (dry) at 6 bar + 3 lt. Per work cycle Water supply 50-60 lt./h at 2-4 bar and 16-24 °C Hardness 8-10 °F Dimensions 130 x 96 x 200(h) cm – 1,540 kg packing 158 x 134 x 215 (h) – 1,770 kg

An automatic unit for surfacing and contouring chains with diamond tipped grinding wheels. Excellent and cost effective for obtain rounded diamond cuts on chains, or an efficient system for removing machining marks on chain surfaces.

Tooling is composed of 4 grinding wheels, (2 roughing and 2 finishing) plus 4 contrast blocks. The machine runs linear chain first through the roughing wheels and immediately afterwards through the finishing wheels. The whole process is carried out with forced lubrication of the grinding process. All of the material removed is recuperated in an adjacent filtering system.

Grinding wheels can be built to match desired contours to various degrees. The wheels can also be regenerated to their original form once consumed.Technical features Grinding wheel speed 2,000 rpm Chain speed 60m/h Maximum chain width 20mm Technical data Voltage (single phase) 400 V 50/60 Hz Power 9 kW Compressed air 7 bar (consumption only at cycle start) Dimensions machine 150 x 110 x 190(h) cm – 575 kg Filtering system 61 x 110 x 103(h) cm packing (h) cm

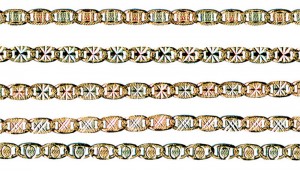

An automatic unit for surfacing cutting chains with diamond tip tools. Tooling can be spindle or wheel. The built in programming feature allows an infinite array of shapes, and characters to be designed onto a chains surface.

The unit works at a high speed thanks to a high precision mechanical positioning system which guarantees rapid and precise movements. The resulting surface is excellently finished since the cutting action is had through an angled action so as to gradually cut into the surface of the link and not directly. This cutting action also minimises the cutting force involved thus prolonging tool life. Characters can be programmed thru the units user friendly control panel, or uploaded from a PC cad file (future upgrade).Technical features Machine speed (based on 0.60 Valentino chain) 4 point star 70/min 6 point star 60/min 8 point star 50/min 12 point star 40/min Butterfly 82/min Double cross XX 52/min Hash # 48/min Number of sequential figures 30 Cutting depth 30 mm Maximum chain width 30 mm Cutting tools Wheel & Spindle Technical data Voltage (single phase) 230 V 50 Hz Power 1.8 kW Compressed air lt./min (dry) at 6 bar Dimensions 82 x 61 x 170(h) cm – 215 kg cm packing 103 x 73 x 187 (h) cm