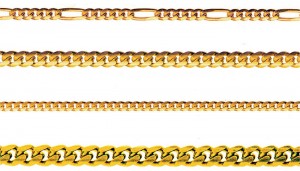

An automatic unit for surfacing and contouring chains with diamond tipped grinding wheels. Excellent and cost effective for obtain rounded diamond cuts on chains, or an efficient system for removing machining marks on chain surfaces.

Tooling is composed of 4 grinding wheels, (2 roughing and 2 finishing) plus 4 contrast blocks. The machine runs linear chain first through the roughing wheels and immediately afterwards through the finishing wheels. The whole process is carried out with forced lubrication of the grinding process. All of the material removed is recuperated in an adjacent filtering system.

Grinding wheels can be built to match desired contours to various degrees. The wheels can also be regenerated to their original form once consumed.Technical features Grinding wheel speed 2,000 rpm Chain speed 60m/h Maximum chain width 20mm Technical data Voltage (single phase) 400 V 50/60 Hz Power 9 kW Compressed air 7 bar (consumption only at cycle start) Dimensions machine 150 x 110 x 190(h) cm – 575 kg Filtering system 61 x 110 x 103(h) cm packing (h) cm